Posted on June 22, 2016 by FDA Voice

By: Jeffrey Shuren, M.D., J.D.

In 1976, Steve Jobs and Steve Wozniak founded Apple and a gallon of gas was $.59. And in another action that has had long term impact, President Ford signed the Medical Device Amendments that closed the dangerous gap between what he called FDA’s “horse and buggy authority” and “laser age problems.”

Jeffrey Shuren, M.D., J.D., FDA’s Director of the Center for Devices and Radiological Health, speaking at FDA’s Celebration of the 40th Anniversary of the Medical Device Amendments

Unlike the pharmaceutical industry, which was born from large chemical companies that discovered medical uses for the products they made, the device industry sprung to life as a scrappy sibling—mostly mom-and-pop businesses addressing the needs of individual patients and physicians through invention.

Although Congress had first given FDA explicit authority over medical devices in the 1938 Food, Drug, and Cosmetic Act, the focus was on fraudulent products. Efforts to extend FDA’s oversight on medical devices failed in 1962 and again in 1970.

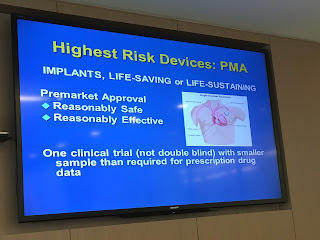

Then in 1975, reports emerged that thousands of women had been harmed, some even died, from pelvic inflammatory disease, as the result of using the Dalkon Shield, an intrauterine device for contraception. Congress responded the following year by enacting the Medical Device Amendments, which authorized FDA to classify all medical devices based on risk into one of three classifications, to require premarket approval for Class III devices, and for devices to comply with reporting and GMP requirements.

The law ushered in a new era for medical technology innovation, patient access, and patient safety, but also created a tension, contributing to a political environment where the pendulum continues to swing between these objectives, defining and driving the medical device ecosystem ever since.

In signing the legislation, President Ford noted that, when “well designed and well-made and properly used” medical devices “support and lengthen life.” But when medical devices are “poorly designed, poorly made, and improperly used” they can “threaten and impair” life.” His words still ring true today.

The initial Medical Device Program started with about 180 people. Today, FDA’s Center for Devices and Radiological Health (CDRH) is 1,700 strong; a vibrant family of individuals with a wide range of scientific, clinical, engineering, legal, and other expertise, who hail from a variety of backgrounds, and who are ready to tackle the latest scientific advancement.

And the mom and pop industry has transformed into a world of sophisticated software algorithms, miniaturization, combination products, wearable sensors, non-invasive procedures and diagnostics, robotics, and artificial intelligence.

Along the way, CDRH has adapted its expertise and regulatory approaches to meet the needs of such rapidly evolving innovation. While we will continue to adapt, more importantly, we are focusing on proactively anticipating where we need to be so that regulatory innovation is out in front of medical device innovation. We’re doing this now in the digital health space, by designing regulatory frameworks around the type of technology and its unique evidence generation and innovation cycle rather than applying a one-size-fits-all approach.

We are implementing new models for evidence generation. They include the establishment of a National Evaluation System for health Technology, or NEST, that could transform the historical tension between device innovation, patient access and patient safety into an alignment of interests to drive the development and more timely access to life-saving, life-enhancing, and life-advancing devices. This is consistent with our vision: That patients in the U.S. have access to high-quality, safe and effective medical devices of public health importance first in the world.

And we are also going to new places with patients by establishing a foundation for engaging with them as our partners and routinely incorporating their perspectives in our decisions. And that’s fitting because improving the health and the quality of life of patients by assuring they have timely access to medical technologies that will benefit them is at the heart of who we are and what we do.

As we look ahead to the future, it is our work, our care and our dedication that will allow us to reach our vision.

Jeffrey Shuren, M.D., J.D., is FDA’s Director of the Center for Devices and Radiological Health

.entry-content

This entry was posted in Innovation, Medical Devices / Radiation-Emitting Products and tagged 40th anniversary of the medical device amendments, FDA's Center for Devices and Radiological Health (CDRH), FDA’s oversight on medical devices, National Evaluation System for health Technology (NEST) by FDA Voice. Bookmark the permalink.

http://www.fda.gov/NewsEvents/Speeches/ucm508146.htm

Remarks at FDA’s Celebration of the 40th Anniversary of the Medical Device Amendments

Remarks of Jeffrey Shuren, M.D., J.D.

Director of the Center for Devices and Radiological Health

U.S. Food and Drug Administration

June 22, 2016

1976.

Anyone thought about where they were or what they were doing in 1976?

I was in junior high school with no clue what the FDA was but very focused on a girl I had a crush on.

In 1976, Nadia Comaneci won 3 gold medals in gymnastics in Montreal.

The Steelers won the Super Bowl.

Steve Jobs and Steve Wozniak founded Apple.

The first “punk rock” single—by a group called The Damned—flopped horribly.

A gallon of gas was $.59 and the Dow Jones Industrial Average closed the year at 1004.

And, as we know and are here today to celebrate, President Ford signed the Medical Device Amendments that closed the dangerous gap between what he called FDA’s “horse and buggy authority” and “laser age problems.”

How we got here has been quite a journey. We’ve been using medical devices for thousands of years, including tools to punch holes in the skull to let out evil spirits and sticks to help the disabled walk. In 1850, a German scientist, Hermann von Helmholz, invented one of the first modern day medical devices, the ophthalmoscope, using a light source and lenses to view the interior of the eye.

At about the same time, Willhelm Roentgen, a professor of physics in Bavaria, discovered that radiation can penetrate solid objects of low density, which led to the invention of X-ray machines. In 1927, the respirator was introduced. In 1939, the first heart-lung bypass machine came on the market.

However, unlike the pharmaceutical industry, which was born from large chemical companies that discovered medical uses for the products they made, the device industry sprung to life as a scrappy sibling—mostly mom-and-pop businesses addressing the needs of individual patients and physicians through invention.

I’ll give you an example: Earl Bakken and his brother-in-law Palmer Hermundslie co-founded Medtronic in 1949 in a garage in Minneapolis. The company started as a repair service for hospital electrical equipment and a regional distributor for other manufacturers. They would build new equipment on order or customize standard instruments for laboratory or clinical researchers. They would install equipment, train personnel on their use, troubleshoot and repair it as necessary. At the time, they were barely getting by.

Enter Walton Lillehei. This world-renowned cardiac surgeon at the University of Minnesota pioneered techniques for the repair of congenital defects as part of the rapidly evolving field of open heart surgery.

Despite successful repair of the congenital defect, about 1 patient in 10 developed post-operative, complete heart block due to damage of the conducting system while the surgical repair was being performed. It was thought that temporary cardiac rhythm support via pacing would keep the patient alive until recovery of the conducting system occurred. However, the high voltage pacing stimuli delivered across the chest by the machine invented by Zoll was believed to be too traumatic on young children.

Dr. Lillehei and his co-workers developed the myocardial wire – a multi-stranded, braided stainless steel wire in a Teflon sleeve that could deliver low voltage pulses. One end of this wire was implanted directly into the heart muscle and the other end was connected outside the body to the physiology lab stimulator.

Early attempts to use the device were successful until October 31, 1957, when a 3-hour municipal power failure resulted in the tragic death of a baby. The hospital had emergency power generation in its surgical suites and recovery area but not in its patient rooms.

The very next day, Lillehei asked Bakken to see if Medtronic could come up with something better.

Initial attempts at building a more reliable and portable pacemaker involved adding an automobile battery with an inverter to convert 6 volts direct current into 115 volts alternating current.

This didn’t work. So, Bakken found a back issue of Popular Electronics where he had seen a circuit for an electronic, transistorized metronome. He modified the two-transistor circuit and placed it, without the loudspeaker, into a four-inch-square and inch-and-a-half-thick aluminum box with terminals and switches on the outside. The circuit was run by a miniature 9.4 volt battery housed within the box.

From that determination and ingenuity sprung the field of “medical electronics.” Prior to 1957, there had never been a partly or completely implantable electrical device.

Every journey brings new inspiration and experience—and, inevitably, bumps, potholes, and dead ends.

Following Medtronic’s early success, the pace of innovation picked up dramatically. But, the transition from garage to manufacturing facility didn’t always include rigorous scientific and clinical evaluation. Instead, it continued to rely on bedside observation for benefit and risk determinations.

Which led to problems. And tragedy.

Congress first gave the FDA explicit authority over medical devices in the 1938 Food, Drug, and Cosmetic Act, with our focus primarily on fraudulent products. However, in 1962 when Congress passed a new regulatory framework for drugs, they dropped President Kennedy’s proposal to include medical devices.

Then in 1970, President Nixon established the Cooper Committee – chaired by Dr. Theodore Cooper, then director of the National Heart and Lung Institute – to study medical devices as part of the President’s endorsement of medical device legislation. The committee recommended that any new legislation be specifically targeted to the device industry, because devices presented entirely different issues from drugs. It also suggested that different classifications for medical devices be created, which would tailor the regulatory controls to the risks involved. But Congress couldn’t agree on a bill.

In 1975, reports emerged that thousands of women had been harmed, some even died, from pelvic inflammatory disease, as the result of using the Dalkon Shield, an intrauterine device for contraception. Congress responded by enacting the Medical Device Amendments, which authorized the FDA to classify all medical devices based on risk into one of three classifications, to require premarket approval for Class III devices, and for devices to comply with reporting and GMP requirements.

The law ushered in a new era for medical technology innovation, patient access, and patient safety, but also created a tension, contributing to a political environment where the pendulum continues to swing between these objectives, defining and driving the medical device ecosystem ever since.

“Today, devices are routinely implanted in our bodies. They replace limbs, bones, tissues, even entire organs. They permit treatment of forms of illness that can be accomplished in no other way. They magnify and speed 10 thousandfold the diagnostic power of the human eye and brain.

“Medical and diagnostic devices have produced a therapeutic revolution, but in doing so they have also become more complex and less easily understood by those who use them. When well designed, well made, and properly used they support and lengthen life. If poorly designed, poorly made, and improperly used they can threaten and impair it.”

While I’d like to take credit for those words—I can’t. While they sound suspiciously recent—they are not.

These are President Gerald Ford’s words—a succinctly accurate and descriptive summary of why, in 1976, America desperately needed the law he was signing to allow the FDA to regulate medical devices based on risk.

Medical devices can save and give us better lives. I know because my family has relied on them for years – from cardiac stents to implantable hips to the mammogram that picked up my wife’s cancer in time to get her the treatment she needed. But we can rely on these medical miracles because of the careful oversight we provide here at CDRH.

When my wife had to decide what course of treatment to pursue, she was given the results of a laboratory developed test. However, it wasn’t until she and I had the results from an FDA-approved test that we had the information and the confidence we needed to make fully informed decisions.

It is our work, our care, and our dedication that will allow us to reach our vision—that patients in the U.S. have access to high-quality, safe and effective medical devices of public health importance first in the world.

CDRH’s vision—our shared vision – intentionally begins with “patients” because improving the health and the quality of life of patients by assuring they have timely access to medical technologies that will benefit them is at the heart of who we are and what we do.

After 40 years, we live in a world of sophisticated software algorithms, miniaturization, combination products, wearable sensors, non-invasive procedures and diagnostics, robotics, and artificial intelligence. And, all along the way, we at CDRH have had to adapt our expertise and regulatory approaches to meet the needs of rapidly evolving innovation. That has been our history.

Make no mistake: We are as scrappy and as enterprising as the industry we regulate.

As we look to the future, however, we will continue to adapt, but, more importantly, we will and have already begun to focus on proactively anticipating where we need to be so that regulatory innovation can get out in front of medical device innovation. We’re doing this now in the digital health space, by designing regulatory frameworks around the type of technology and its unique evidence generation and innovation cycle needs rather than applying a one-size-fits-all approach.

And we are implementing new models for evidence generation, such as through the establishment of a National Evaluation System for health Technology, or NEST, that could transform the historical tension between device innovation, patient access and patient safety into an alignment of interests to drive the development and more timely access to life-saving, life-enhancing, and life-advancing devices.

We are going to new places with the patients who drive our mission, by establishing a foundation for routinely incorporating their perspectives in our decisions. After all, they are our most important customer and should be our partner in best serving them.

Forty years ago, the initial Medical Device Program started with about 180 people, and our country was celebrating its 200th anniversary. That year, NASA unveiled its first space shuttle – The Enterprise – which, as a Star Trek fan, I thought was very, very cool. As a nation we were ready to soar.

Forty years later, CDRH is 1,700 strong; a vibrant family of individuals with a wide range of scientific, clinical, engineering, legal, and other expertise, who hail from a variety of backgrounds, and who are ready to tackle the latest scientific advancement, including what one day soon may be the first Star Trek-like tricorder. While our mission and vision guide us, and patients drive us—it is our people and their diverse personal and professional backgrounds, experiences, and expertise who are fundamental to our success as a public health agency.

If our mission and vision are our North Star, if patients are our compass, then our ship – our USS Enterprise – that will boldly go where no person has gone before – is CDRH, and you are its crew.

Captain James T. Kirk once said, “You know the greatest danger facing us is ourselves, an irrational fear of the unknown. But there’s no such thing as the unknown — only things temporarily hidden, temporarily not understood.”

I don’t know what new worlds we will discover or the new technologies we will encounter, but I look forward to traveling there with you wherever we may go.

Happy anniversary.